Cookie Settings

We use cookies to operate this website, improve usability, personalize your experience and improve our marketing. Your privacy is important to us. Privacy Policy.

Applications

AI agents built for AI factory optimization

Our AI agents are trained specifically to maximize AI factory energy efficiency and reliability.

Phaidra provides a suite of AI agents that enable your AI factory to continuously run at peak performance.

We developed these AI agents to handle specific operational challenges, including:

- Minimizing energy consumption.

- Eliminating the thermal spikes (and therefore GPU throttling) from sudden IT load changes.

- Helping plant operators identify and troubleshoot issues in minutes rather than days/weeks.

At the heart of our mission lies a simple observation: inefficiencies get magnified at gigawatt-scale. AI factories today are so large and integrated that they must utilize new technologies capable of handling 10x higher complexity. After all, AI factories only reach peak productivity when they operate as a single cohesive system.

This is where our AI agents shine. Our agents behave as Virtual Plant Operators — virtual members of your operations staff — designed to monitor, learn, and adjust autonomously (i.e. no human supervision). The end result is higher efficiency without sacrificing reliability.

“

These companies, along with a growing ecosystem of specialists in infrastructure design, simulation, and orchestration — including Cadence, Emerald AI, E-Tech Group, Phaidra, PTC, Schneider Electric, Siemens and Vertech — are helping NVIDIA activate a system-level transformation. At the heart of this vision lies a fundamental challenge: how to optimize every watt of energy that enters the facility so that is contributes directly to intelligence generation.

”

NVIDIA blog post announcing the partner ecosystem for design, construction and operations of AI Factories - September 9, 2025

Meet the agents

Phaidra’s suite of AI agents is developed by experts in AI and data centers. Our team comes from DeepMind, Google, Microsoft, AWS, and Trane Technologies.

These AI agents utilize reinforcement learning and LLMs to perform discrete tasks — such as managing liquid cooling CDUs or instantly analyzing large amounts of sensor data — to operate the entire AI factory more efficiently and reliably.

Discrete agents for specific challenges

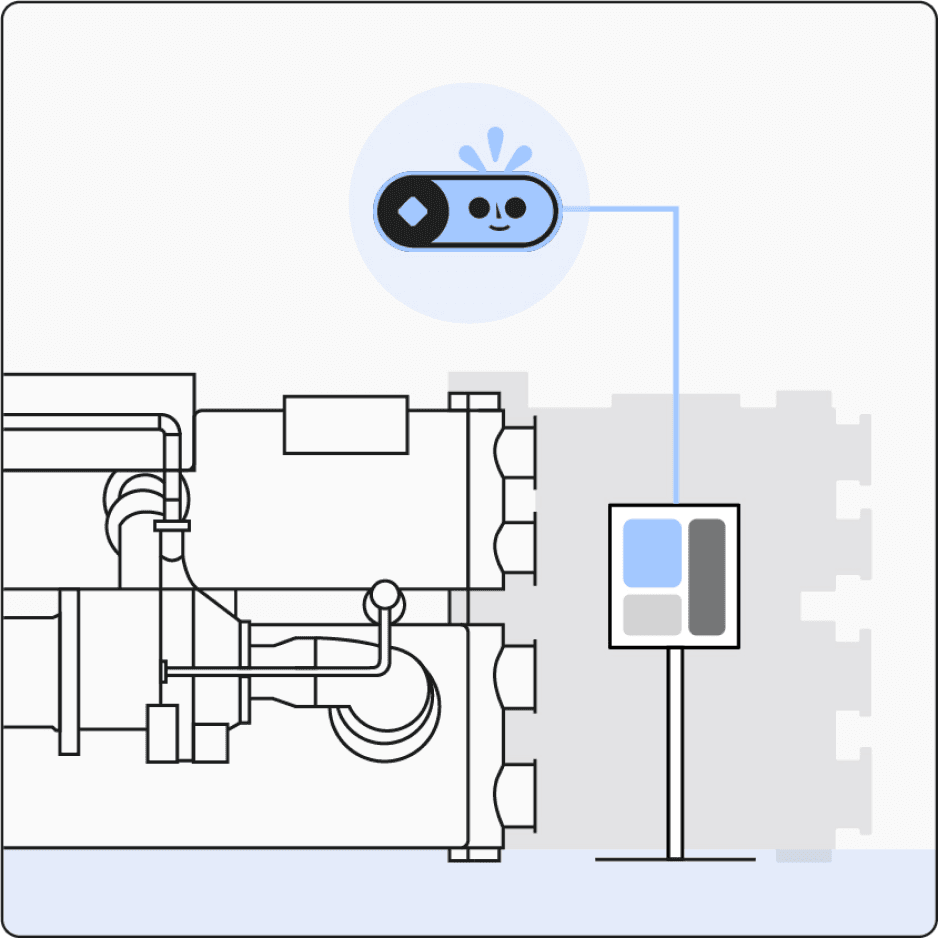

Liquid cooling agent

CDU control (rack and row-level)

Challenge: Large GPU clusters with synchronized workloads cause sudden IT load spikes, which in turn cause thermal spikes. These thermal spikes force the facility to run at significantly lower TCS temperatures to avoid GPU throttling.

Solution: AI agent that anticipates thermal spikes before they occur and preemptively controls the CDU to reduce or eliminate the spike.

Result: Precision TCS thermal control within 0.5C (i.e. 80+% reduction in the magnitude of thermal spikes). This enables the AI factory to run at significantly higher TCS temperatures while meeting SLAs — meaning higher energy efficiency and IT capacity.

Chiller plant agent

PUE optimization

Challenge: The cooling system is the largest component of DC overhead (typically ~70% of non-IT loads). Traditional control systems deliver reliability at the expense of energy efficiency — our AI agent can do both simultaneously.

Solution: AI agent that intelligently and proactively manages the chiller plant (e.g. chiller staging, evaporator temps, differential pressures, etc.) via a BMS/SCADA integration.

Result: Significant PUE improvements arising from a large reduction in chiller plant energy consumption. Improved SLA compliance.

Insights agent

“Jarvis for data centers”

Challenge: AI factories generate overwhelming amounts of sensor data and complexity. Furthermore, data is siloed across multiple platforms (e.g. BMS, PMS, Ignition, OEM manuals, SOO, etc.), impeding operational efficiency.

Solution: An LLM-based analytics and observability platform that enables DC owners and operators to query information instantly — and across all systems — in a natural language manner.

Result: Data retrieval, analyses, and troubleshooting that would normally take days or weeks now take minutes.

Autonomous AI Controls at Merck: Mission Critical Cooling Optimization

Case Study: Learn more about the journey to full autonomous AI control deployment and the impacts that Virtual Plant Operators are having at Merck's largest manufacturing site.

“

[We] always believed that the most transformative companies are those that marry profit with purpose. Phaidra is tackling AI's biggest bottleneck, energy consumption, in collaboration with NVIDIA, the global leader in compute.

”

Sophie Bakalar, Partner at Collaborative Fund & member of Phaidra’s Board of Directors

Subscribe to our blog

Stay connected with our insightful systems control and AI content.

You can unsubscribe at any time. For more details, review our Privacy Policy page.